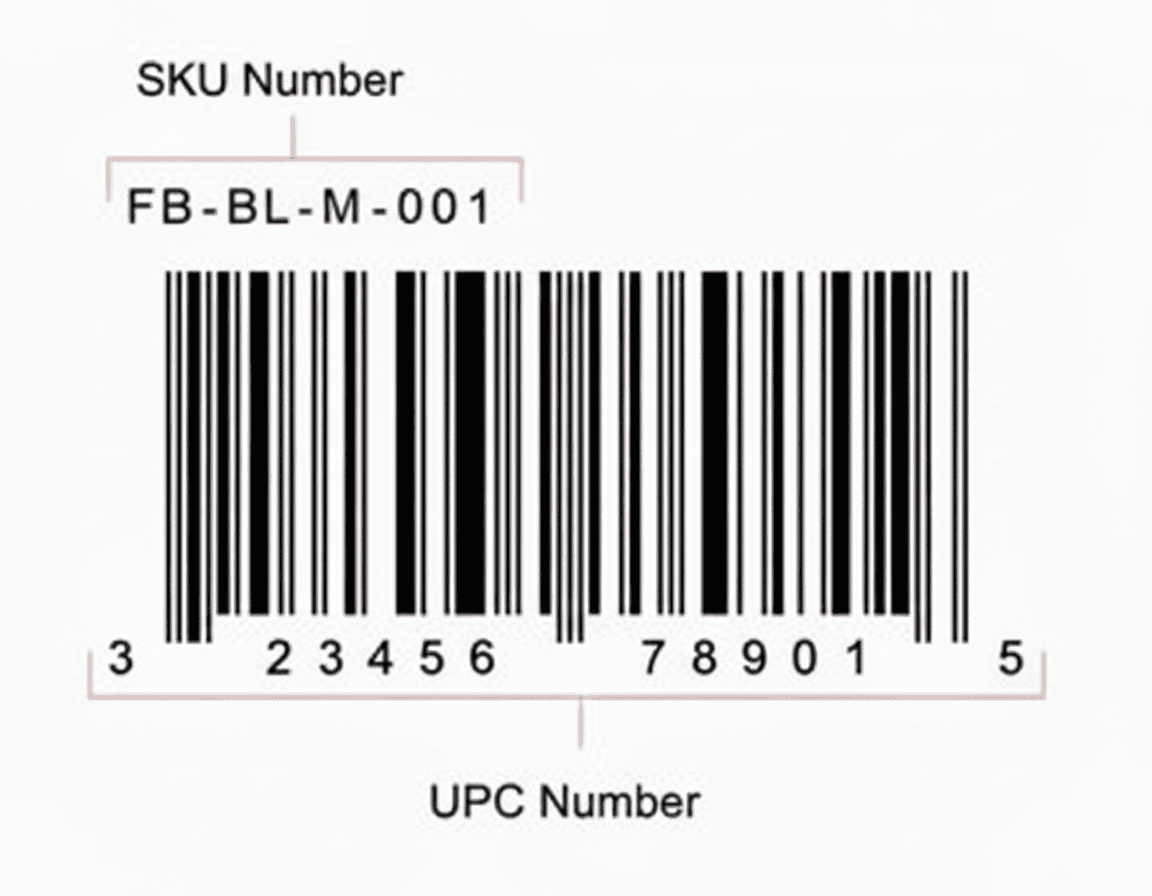

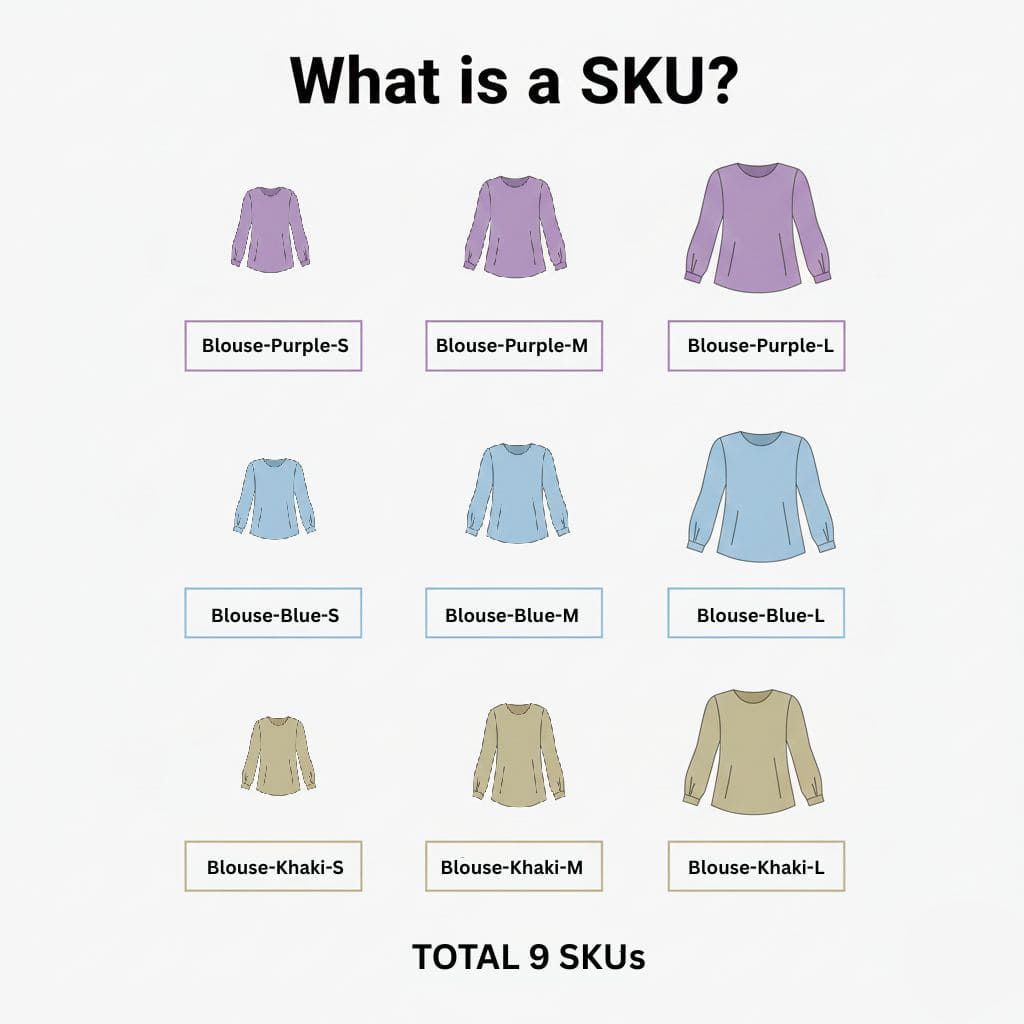

A well-designed SKU system can transform your inventory management strategies. Here’s how:

1. Monitor trends and inventory levels

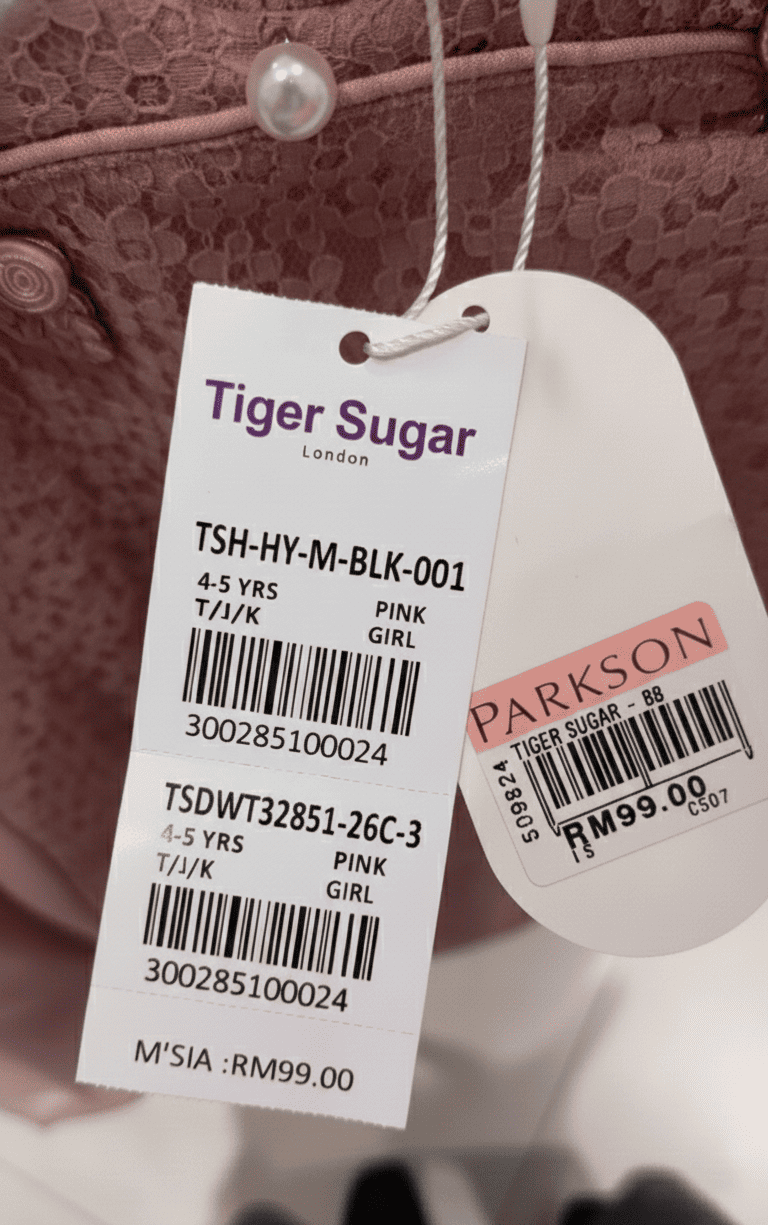

Each product has a unique SKU, allowing detailed tracking of sales by product attributes. With SKU-level visibility:

- You can identify which items sell quickly and which linger on shelves.

- Reduce phantom inventory (stock that appears in the system but isn’t physically available).

- Anticipate stockouts and reorder in time.

Example: If a medium blue T-shirt sells out faster than small or large sizes, SKU data helps you restock exactly what’s needed rather than guessing.

2. Calculate reorder points

SKU data allows businesses to define precise reorder points based on past sales trends, lead times, and seasonal variations.

- Helps avoid excess inventory or stock shortages.

- Supports automated replenishment systems to reduce manual errors.

- Prevents tying up cash in slow-moving items.

Example: If SKU TSH-M-BLK-001 sells 10 units per week and supplier lead time is 2 weeks, your reorder point would be around 20 units. Automated alerts can trigger purchase orders immediately.

3. Forecast demand and sales

Using SKU-level data, businesses can reliably know which specific product variants customers buy most often,

able to accurately predict inventory requirements and plan staffing:

- Forecast demand by SKU for busy weekends, holidays, or seasonal peaks.

- Identify slow-selling SKUs and reduce overstock.

- Adjust marketing and promotions to optimize sales.

Example: A retailer notices that red hoodies sell 50% faster than other colors in winter. They can increase stock and promotional campaigns for red hoodies to maximize revenue.

4. Plan product displays

SKU data informs visual merchandising decisions:

- Highlight fast-moving or high-margin products at eye level.

- Group slow-moving items strategically to increase visibility.

- Plan online layouts by product popularity and stock availability.

Example: Moving a mid-tier item from bottom shelf to eye level could boost sales by 30–40%, based on shelf placement experiments.

5. Improve the customer experience

- Accurate SKU tracking ensures items are available when customers want them.

- Minimizes inventory errors that frustrate shoppers.

- Provides quick order retrieval for faster checkout and fulfillment.

Example: A customer looking for a medium black T-shirt can be confidently told the SKU is in stock across multiple store locations. iDCP POS system able to show which SKU at which outlet in real-time.